Smarter Storage

Smarter Storage

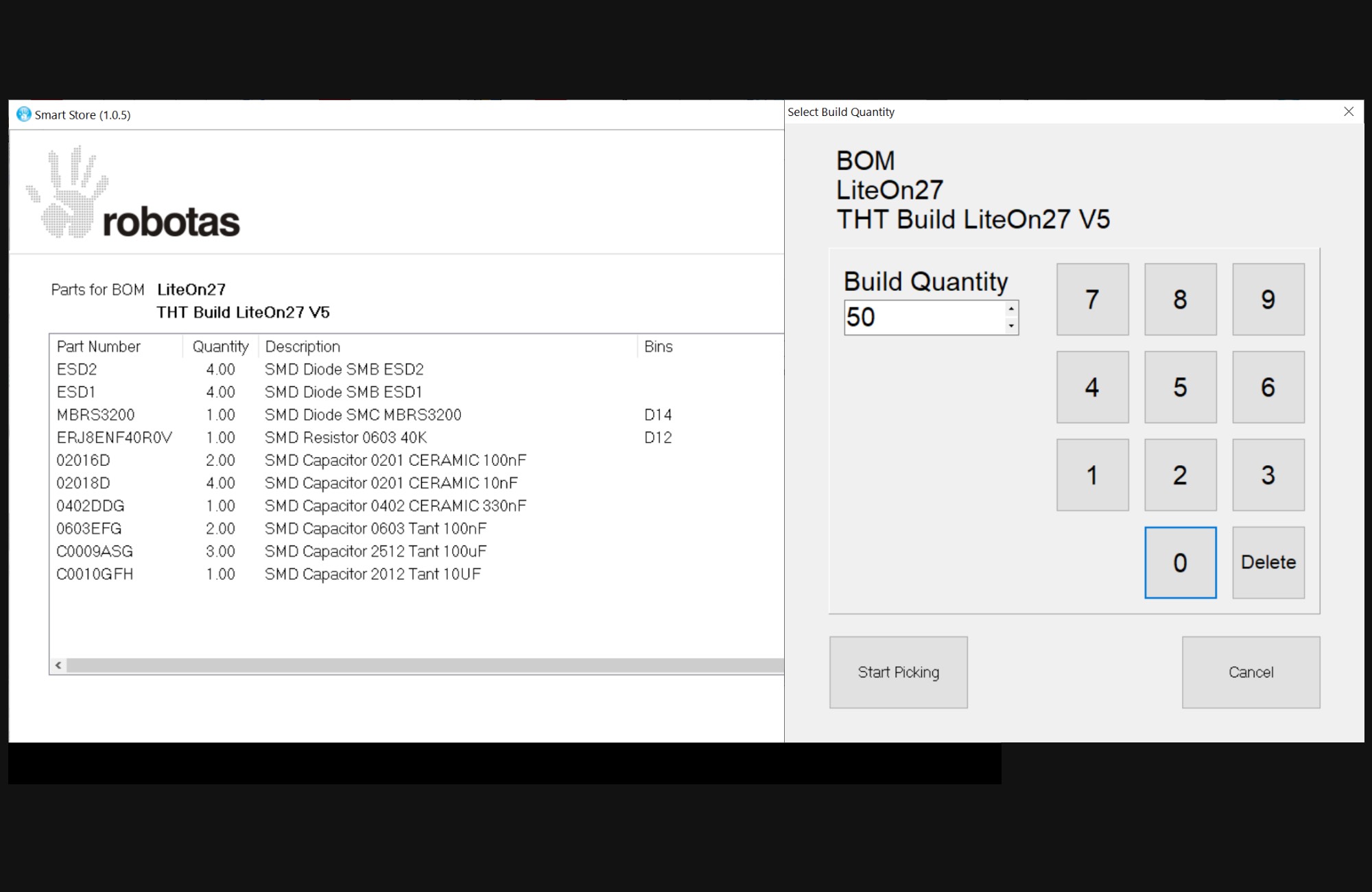

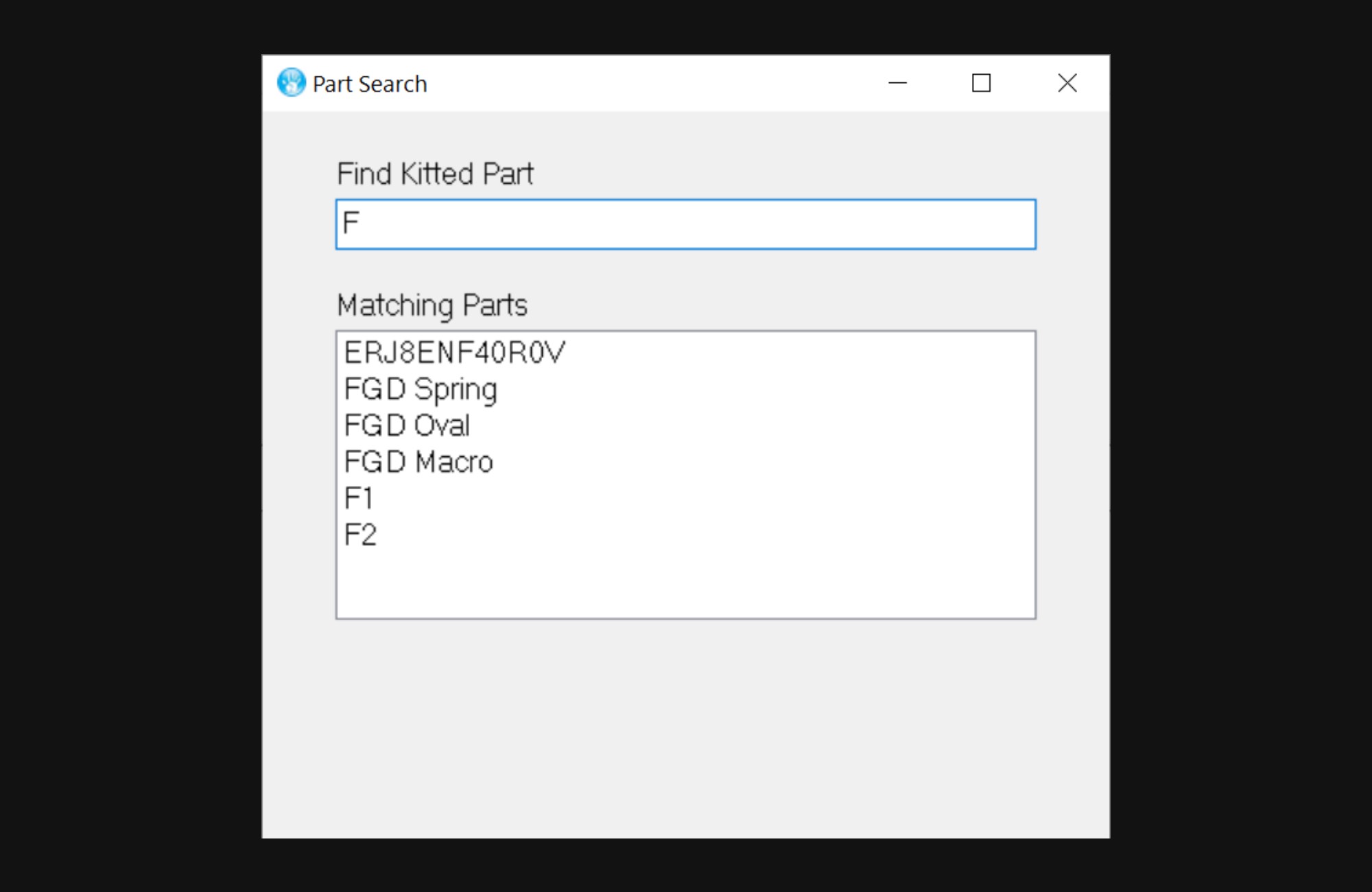

Optimise your Line side Production

The move in modern production to have line side storage on the production floor ( where the required material is kept close to the production line) has provided smoother transfer of material on to the production floor. However, it has also led to some issues. Often line side storage is set out in a similar manner to conventional main stores with row and column identification. Material and parts to be retrieved are often on a paper list, material stock levels can get out of sync with the production requirements leading to production delays. Multiple operators picking material that uses up valuable production time.